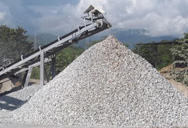

primary jaw crusher

Laboratory and pilot plant Primary Jaw Crushers - FLSmidth

The heavy-duty, general purpose Essa JC3000 Jaw Crusher is a well proven, highly productive primary crusher used in sample preparation and plant applications. More

More

Influence of jaw crusher parameters on the quality of primary

2020.6.1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher

More

McLanahan Jaw Crushers

Jaw Crushers. Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and

More

Jaw Crushers – MEKA

DESCRIPTIONS ABOUT Jaw Crusher DOWNLOADS APPLICATIONS Primary and secondary crushing applications for quarrying, mining, recycling and industrial minerals. Toughest feed materials, Stationary,

More

Nordberg® C Series™ jaw crushers - Metso

Features. Nordberg® C Series™ jaw crushers are mainly used as primary crushers in aggregates production, mining operations and recycling applications. The product family consist of models of different sizes that

More

Comec - Serie P Primary Jaw Crushers

The primary jaw crusher of the P Series is ideal for heavy-duty applications. Its robust design, large diameter of the shaft and reinforced bearings have been shown to

More

Jaw Crushers - thyssenkrupp Polysius

For crushing middle hard to hard and abrasive materials in primary and secondary crushing applications for low and high capacities. Single-toggle jaw crushers are characterized by the swing jaw being suspended

More

Jaw crushers, Stationary Jaw crusher series - SRP

Sandvik jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are delivered with everything you need for plug-and-play installation and

More

Nordberg® C160™ jaw crusher - Metso

Nordberg® C160™ jaw crusher for high-capacity primary crushing. Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of

More

Optimal energy management for a jaw crushing process in

2014.4.15 primary jaw crusher: a compressive crusher machine used for crushing of coarse and hard ROM ore;-ore bin: a storage equipment to receive the crushed ore material that will be later conveyed to the shaft station. 2.2. General assumptions for the system. 1.

More

Jaw Crushers – MEKA

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. There are also primary

More

Nordberg® C160™ jaw crusher - Metso

Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day. Based on customer experience and comprehensive testing, the critical areas of Nordberg® C160™ jaw crusher are protected against wear. The vital parts are also quickly ...

More

Jaw Crusher - Heavy Duty Jaw Crusher Latest Price,

Roljack Asia Limited. Contact Supplier. Delhi Scientific Mild Steel Jaw Stone Crusher Manufacturer, Capacity: 300 KG To 500 Ton Per Hour. ₹ 50,000. Delhi Scientific. Contact Supplier. Mild Steel 48"x36" (1200x950mm) - Primary Jaw Crusher. ₹ 65 Lakh. Deepa Machinery Manufacturers Private Limited.

More

Influence of jaw crusher parameters on the quality of primary

2020.6.1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates. The study is focused on the production of all-in large-size (top size ⩾90 mm) aggregates, suitable for use in subbase

More

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 In the aggregate industry, for tonnage outputs less than 1000 metric tons per hour, jaw crushers are the dominant type of primary crusher. Jaw crushers All jaw crushers are distinguished by the presence of two plates, one of which is fixed and one that swings open and then closes, concurrently trapping and crushing material between the

More

Crushers - All crusher types for your reduction needs - Metso

To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Also, primary gyratories require quite a massive foundation. Primary crushing with impact crushers. The primary impact crusher offers high capacity and is designed to accept large feed sizes. The primary impact crushers ...

More

Laboratory and pilot plant Primary Jaw Crushers - FLSmidth

Essa JC3000 Jaw Crusher . The heavy-duty, general purpose Essa JC3000 Jaw Crusher is a well proven, highly productive primary crusher used in sample preparation and plant applications. More powerful than the JC2000, it is suitable for higher workloads and can handle large core and lump crushing.

More

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

More

Primary Crusher - an overview ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

More

Primary Crusher Selection Design - 911 Metallurgist

2015.12.23 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone

More

TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW

2021.4.7 WORLD LEADING JAW CRUSHER SERIES The QJ341+ jaw crusher comes equipped with a primary pan feeder, double deck independent pre-screen and extended telescopic natural fines conveyor as standard. The pre-screen features a stepped grizzly, under screen mesh and carrying rubber. This system has been designed to work

More

MC 110i EVO2 Mobile jaw crushers Kleemann - Wirtgen

The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.

More

Designing a Crushing Screening Plant – Part I. Primary Jaw

2020.10.27 Jaw crusher stage with a screen in the grizzly by-pass to extract a 0-90 mm product. Figure 5. Jaw crusher stage with a screen that process all material and allows for production of 0-30 mm, 0-60 mm or 0‑90 mm. Figure 6. The rock size varies in the muck pile, as seen in the picture the number of large rocks is far greater on the right side.

More

Advantages of Primary Jaw Crusher - LinkedIn

2023.3.8 Primary jaw crushers are widely used in mining, quarrying, and aggregate production industries, and have numerous advantages over other types of crushers. ... 200tph rock jaw crusher price Mar 9 ...

More

What Is A Jaw Crusher - MEKA

The nip angle in primary is lower than in secondary . Generally, this value is between 18 and 24 degrees in primary, and between 22 and 28 degrees in The nip angle can be 33 degrees maximum. WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES. There are two main groups of jaw crushers, categorized according to their jaw

More

Primary jaw crusher development (Technical Report)

Conventional equipment has been evaluated for the primary and secondary crushing steps. This report evaluates roll crushers that are proposed for the tertiary and final stage of crushing, and gives the status as of June 16, 1975. 18 figures.

More

The Complete Guide to Primary Crushing, Secondary

2023.2.28 The working principle of primary crushers varies depending on the type of crusher, but generally, they work by reducing the size of the material through compression or impact. In jaw crushers, the material is fed into the crushing chamber and is crushed between a fixed jaw and a movable jaw.

More

Concrete aggregates properties crushed by jaw and

2019.1.1 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates. The proportion of particles finer than 0.15 mm is around 7–8% weight for both crushing

More

Primary Jaw Crusher Stone Crusher FUREIN Machinery

2024.1.8 Primary Jaw Crusher. Feed size: 125~1020mm. Capacity: different models with different output, as a professional jaw crusher manufacturer, we supply you with primary jaw crusher capacity at 1-800t/h. Application: Primary jaw crusher is mainly used for crushing medium-size stone and large materials, widely used in mining, smelting, building ...

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Primary crusher Jaw crusher Expt. + Nume FEM analysis can be used as a powerful tool for analyzing the failure of the component in jaw crusher 2013 Rusi´ nski et al. [16] Poland 3 Primary crusher Jaw crusher Expt. + Nume Regression analysis was done in order to find out the effect of mechanical properties ofrock onthespecific power ...

More

jaw crusher_百度百科

编辑. Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc.

More

Jaw crushers, Stationary Jaw crusher series - SRP

Sandvik Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor

More

what is a primary and secondary crusher? - LinkedIn

Published Feb 10, 2023. + Follow. Primary crushers and secondary crushers are used in the mining and quarrying industry to crush rocks and aggregate, respectively. A primary crusher is a heavy ...

More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023.5.27 Jaw crushers: The first choice for primary crushing The jaw crusher is popular because it crushes big rocks into smaller sizes easily. Thus, it proves itself as an effective primary crusher in aggregate, mining, recycling, and concrete industries. It can handle very soft to very hard materials and has no abrasion limit.

More

Development of a model estimating energy consumption values of primary ...

2014.1.17 Also, jaw type crusher was used as primary crusher and hammer type as secondary crusher for crushing the material blasted at both work fields. Especially, open pit quarry enterprises producing aggregate of a 7.5-cm dimension will be able to estimate energy consumption values of the crushers by using this model.

More

Jaw Crusher - Primary Jaw Crusher Manufacturer from

Our company holds immense experience in this domain and is involved in offering a wide assortment of Stone Crusher Manufacturing. Our single toggle Jaw Crusher has a crushing capacity of 36tph for 20mm Jaw setting. And, 60 tph for 40mm Jaw setting. Feeding size is 6inches. It's a complete oil lubrication Machine.

More

Vibration Insulation for Jaw Crushers ― an Effective

2017.8.27 jaw crusher Concrete floor G-7 G-4 Fig. 1.Building housing primary-crushing unit. a) section; b) foundation of SMD-60A jaw crusher; c) settlement curves of column foun-dations in axes G-4 and G-7. Dynamic load Indicators harmonic pulse Peak force, kN horizontal vertical 116 138 3500-Frequency of force effect, Hz 2.08 60 Distance

More

Primary and Secondary Crushing: Understanding the Basics

2023.2.28 The primary crusher receives the materials directly from the mine or quarry, and its size reduction ratio ranges from 3:1 to 7:1. The primary crusher can be a jaw crusher, gyratory crusher, or impact crusher, depending on the hardness, abrasiveness, and size of the materials. The jaw crusher is the most common type of primary crusher used

More

Our Range of Trio® Jaw Crushers Weir

The biggest difference between the Trio® CT Series and the Trio® CTHT Series jaw crusher is that the toggle cylinder within the CTHT is used to adjust the CSS and provide overload protection. Applications. Our range of Trio® jaw crushers are designed for tough primary crushing within mining, aggregate and recycling applications. Within the ...

More- كسارة حجر الموردين وأسعار

- مخطط التدفق 100tph محطة كسارة الحجر

- تفسير الغربال في الحلم

- الشركات المصنعة للكسارات المحمول في الصين

- الشركات المصنعة كسارة الكهربائية الجليد

- مطاحن الكرة لتعدين الذهب في المملكة المتحدة

- آسیاب سیمان سنگ زنی خام

- الشاي المطاحن من وكالة الفضاء الروسية

- خام النحاس إثراء شركة في الصين

- محطة إثراء خام المعادن في الهند

- چینی تولید کنندگان تجهیزات معدن

- کمربند مواد نوار نقاله pdf

- سيمونز أجزاء مخروط محطم

- استخدام المعدات في المكسيك التعدين الذهب

- كيفية جعل مطحنة لطحن الزيتون